Custom CNC milling is often viewed strictly through the lens of unit price, yet the total cost of ownership extends far beyond the machine shop floor. For senior manufacturing engineers and procurement directors, the real financial drain frequently lies in the hidden administrative overhead of managing a fragmented supply chain. By consolidating prototyping, precision machining, and surface finishing under a single turnkey provider, organizations can eliminate the friction associated with inter-supplier logistics. This approach not only stabilizes custom CNC milling cost structures but also accelerates the transition from NPI to mass production.

Mitigating Administrative Costs and Quality Risks in Supply Chains

Fragmented procurement strategies force engineering teams to act as logistics coordinators, diverting valuable time from R&D to manage conflicting vendor schedules and quality disputes. Consolidation removes these non-value-added layers.

The Hidden Financial Impact of Multi-Vendor Management

The administrative burden of raising separate purchase orders for machining, anodizing, and assembly is often underestimated. Industry data suggests that the manual processing of a single PO can cost an organization between $50 and several hundred dollars in labor and overhead. When a project requires coordinating five different vendors, these administrative costs compound rapidly. A consolidated model replaces this web of transactions with a single point of contact. This reduction in paperwork directly lowers the operational overhead attached to custom CNC milling services, allowing procurement teams to focus on strategic sourcing rather than clerical management. Furthermore, unified logistics prevent the common “value leakage” that occurs when components are damaged during transit between a machinist and a finishing house, a scenario where neither vendor accepts liability.

Streamlining Liability and Quality Assurance

In a multi-vendor environment, quality control often becomes a blame game. If a plated part fails inspection, the finisher may blame the surface preparation, while the machinist blames the plating process. This “finger-pointing” delays production and increases lead times. A consolidated supply chain establishes a single source of truth for quality. By integrating custom CNC milling with downstream processes like heat treatment and surface finishing, manufacturers create a closed-loop quality system. This ensures that a single entity is accountable for the final component’s conformity to geometric tolerances and cosmetic standards, significantly reducing rework cycles and liability gaps.

Strategic Sourcing: Optimizing Global and Regional Production

Effective supply chain strategies often employ a hybrid approach, leveraging local proximity for immediate needs while utilizing global partnerships for scalable, cost-effective volume production.

The Role of Local Hubs like Custom CNC Milling Savannah

For rapid prototyping and emergency repairs, proximity is a critical asset. Manufacturing engineers often rely on custom CNC milling Georgia based shops for same-day modifications or fixture adjustments. A facility offering custom CNC milling Savannah services can provide the agility needed during the initial design validation phase, where face-to-face collaboration allows for real-time problem solving. These local partners serve as excellent bridges for low-volume, high-mix runs where speed outweighs unit cost. However, as product lifecycles mature and demand volume increases, the capacity constraints and higher labor rates of strictly local shops can become bottlenecks, necessitating a strategic shift toward partners capable of handling mass production.

Scaling with Integrated China CNC Milling Services

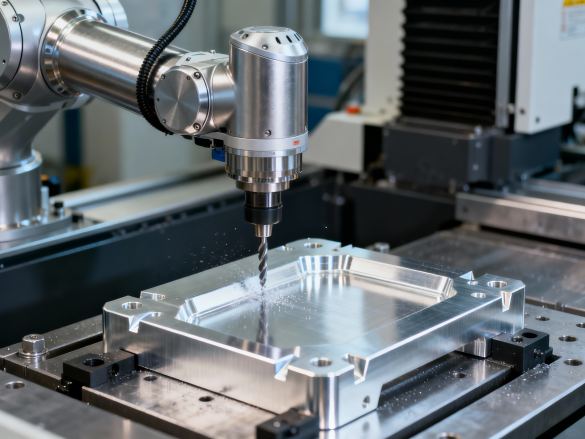

To achieve competitive unit economics at scale, Western OEMs increasingly integrate custom CNC milling services into their broader supply chain. Advanced providers in this region have evolved beyond simple job shops into sophisticated contract manufacturers capable of mirroring the quality standards of their US counterparts. By utilizing zero-point clamping systems and automated pallet pools, these partners facilitate rapid line changeovers and 24/7 “lights-out” manufacturing. This global integration allows companies to transition seamlessly from a local prototype developed in Georgia to a high-volume production run in Asia, ensuring that the custom CNC milling cost remains viable for mass market release without compromising on the precision established during the design phase.

Livepoint Tooling: Precision Manufacturing and Global Integration

Livepoint Tooling delivers a seamless manufacturing experience, combining over two decades of precision expertise with robust global logistics to support complex engineering requirements.

Comprehensive Capability from Prototype to Production

Livepoint Tooling distinguishes itself through a vertical integration strategy that encompasses CNC milling, turning, EDM, and injection molding. With certifications including ISO 9001:2015 and IATF 16949, the company supports demanding sectors such as medical devices and new energy vehicles.Their factory is equipped with advanced processing equipment, capable of achieving tolerance accuracy of up to 0.005 millimeters.By offering in-house surface finishing and assembly, Livepoint eliminates the risks associated with fragmented outsourcing. Their engineering team utilizes advanced DFM (Design for Manufacturing) analysis to optimize tool paths and material selection, ensuring that every project—from a single prototype to a million-part run—adheres to strict quality protocols.

Conclusion

For manufacturers seeking to reduce administrative friction and lower total costs, Livepoint offers a proven pathway to efficient, scalable production.

Contact the engineering team today to audit your supply chain and discover how consolidated manufacturing solutions can optimize your production workflow.