In industries where material management and logistics are crucial, LiDAR volume measurement has become a key technology for improving operational precision. By using laser-based distance detection, this method helps businesses monitor stockpiles, track cargo, and analyze storage spaces with exceptional accuracy. Unlike traditional measuring tools, LiDAR systems work in real time and are highly reliable even in complex environments. Among the companies driving this advancement, Benewake has made significant progress by developing compact and precise LiDAR solutions tailored for industrial applications.

Reliable Measurement in Dynamic Environments

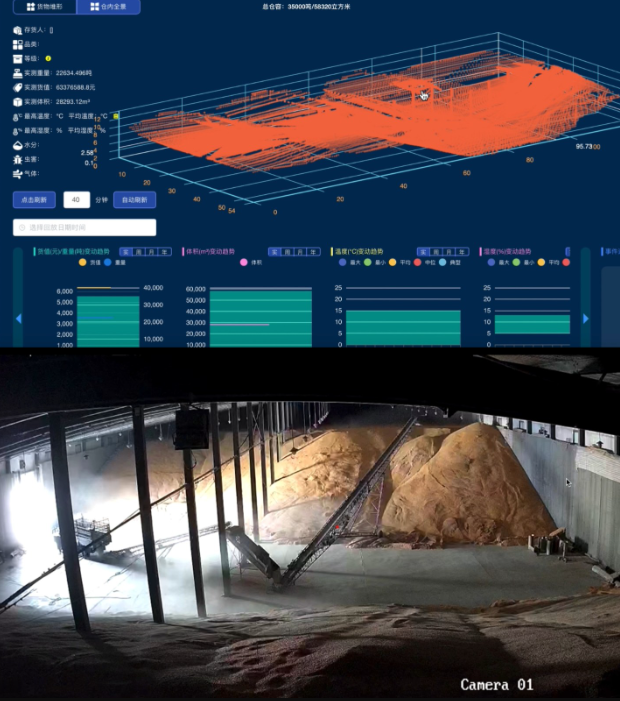

Industrial environments often face challenges such as dust, irregular surfaces, and limited visibility. The LiDAR volume measurement systems provided by Benewake are designed to overcome these issues. Their sensors can be fixed on cranes, silos, or conveyor systems to continuously monitor material volume without physical contact. This ensures safer operations and minimizes manual errors, which are common in traditional measurement processes. The technology also supports efficient data integration, enabling companies to manage inventory and logistics through automated systems.

Practical Applications in Storage and Transport

Benewake’s LiDAR solutions are widely recognized for industrial applications, including mining, logistics, and construction. They offer the LiDAR Volume Detection System, a high-precision module with a 120°×120° wide field of view that generates dense point clouds for accurate volume measurements. The system integrates TF series LiDARs with ranges up to 180 meters, supporting material level, coal pile, and grain silo monitoring. It features multi-line scanning, self-cleaning, wireless transmission, and configurable parameters to optimize real-time volume monitoring. By providing reliable 3D reconstruction and continuous operation, Benewake enables operators to maintain precise, repeatable results while improving efficiency in industrial volume detection tasks.

Conclusion

By integrating Benewake’s advanced LiDAR systems into industrial workflows, companies can achieve more accurate and efficient material management. The use of LiDAR volume measurement technology marks a shift toward smarter, data-supported decision-making in industrial operations. As automation continues to evolve, these reliable sensing systems are set to become even more essential for maintaining productivity and safety in large-scale industrial projects.