When it comes to LED lighting manufacturing, scale and sophistication go hand in hand. MasonLED, a top LED lights manufacturer in China, understands this synergy perfectly. Their Dongguan SongShan Lake Production Base stands as a testament to their commitment to large-scale production without compromising on quality or innovation.

A Tale of Two Areas, United by Excellence:

Strategically located in Dongguan, a global manufacturing hub, MasonLED’s production base is divided into two distinct areas, each dedicated to a specific aspect of the LED lighting ecosystem:

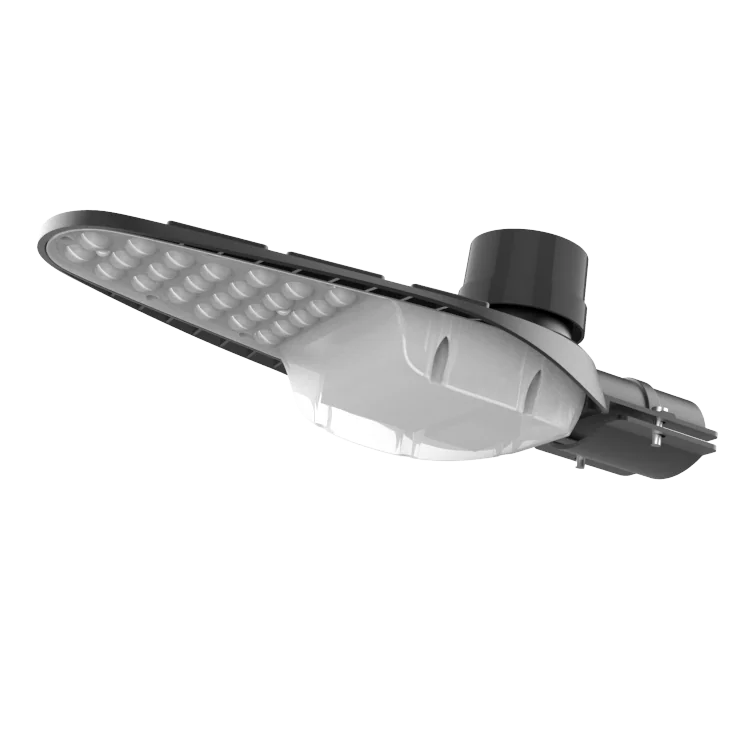

Area A: Where Innovation Meets Assembly:This area is a hive of activity where finished LED lighting products take shape. From sleek streetlights to robust industrial fixtures, skilled technicians and engineers work in unison to assemble, test, and package a diverse range of lighting solutions.

Area B: The Heart of LED Chip Encapsulation: This area delves into the very core of LED technology – chip encapsulation. Here, in a controlled environment equipped with cutting-edge machinery, MasonLED meticulously encapsulates LED chips, ensuring optimal performance, longevity, and light output.

A Scale That Speaks Volumes:

The sheer size of MasonLED’s Dongguan SongShan Lake Production Base is a testament to their manufacturing prowess:

US$300 Million Investment: MasonLED’s significant investment in this facility underscores their commitment to establishing a world-class manufacturing operation.

100,000 Square Meters of Manufacturing Power: This expansive space provides ample room for efficient production lines, advanced equipment, and a dedicated workforce, allowing MasonLED to meet the demands of a global clientele.

Beyond Size: A Commitment to Quality and Efficiency:

While the scale of MasonLED’s production base is impressive, it’s their unwavering focus on quality and efficiency that truly sets them apart:

Vertical Integration: By controlling both LED chip encapsulation and finished product assembly, MasonLED maintains strict quality control throughout the entire manufacturing process.

Advanced Automation: MasonLED leverages advanced automation technologies and robotics to enhance precision, consistency, and efficiency on their production lines.

Lean Manufacturing Principles: Embracing lean manufacturing principles minimizes waste, optimizes processes, and ensures that every product meets MasonLED’s high standards of quality.

A Global Reach, Rooted in Manufacturing Excellence:

MasonLED’s Dongguan SongShan Lake Production Base serves as the backbone of their global operations. From this state-of-the-art facility, they are able to:

Meet Diverse Market Demands: Their large-scale production capabilities and flexible manufacturing processes allow them to cater to a wide range of lighting needs across various industries and applications.

Maintain Competitive Pricing: Efficient manufacturing practices and economies of scale enable MasonLED to offer competitive pricing without compromising on quality.

Drive Innovation: The close proximity of their R&D team to the production base fosters a culture of continuous improvement, allowing them to quickly translate innovative ideas into tangible products.

Conclusion:

MasonLED’s Dongguan SongShan Lake Production Base is a testament to their position as a top LED lights manufacturer in China. It’s a place where cutting-edge technology, skilled craftsmanship, and an unwavering commitment to quality converge to illuminate the world with brighter, more efficient, and more sustainable lighting solutions.