The modern industrial landscape is characterized by increasing miniaturization, intricate assembly, and the widespread adoption of collaborative robots (cobots) designed to work in confined areas alongside human operators. This shift presents a fundamental challenge to traditional vision systems: how can high-precision 3D data be reliably acquired within a small, often cluttered workspace where space, weight, and cycle time are critically limited? Achieving high-precision 3D measurement in these constrained environments is not simply about shrinking hardware; it requires a specialized vision technology that maximizes data density and accuracy while minimizing the physical footprint. This need has driven innovation toward compact structured light solutions, exemplified by the advanced DLP camera systems used by Transfer3D.

The Challenge of Precision in Constrained Spaces

Industrial automation frequently demands precise handling of small or complex parts for tasks such as electronics assembly, machine tending for small components, and intricate quality inspection. In these scenarios, the required measurement accuracy is often measured in tenths of a millimeter or less. Traditional vision systems struggle here for several reasons: large Time-of-Flight (ToF) cameras lack the necessary close-range precision, while bulky scanners obstruct the very space the robot needs to operate. Furthermore, cameras designed for large fields of view lose data density when focused on small, nearby objects.

The solution lies in the specialized design of a structured light system that is both ultra-compact and utilizes high-fidelity projection. The ideal small-workspace 3D camera must be light enough to be mounted directly onto a collaborative robot’s arm without compromising payload or speed. Simultaneously, it must maintain a short Baseline (the distance between the projector and the camera lens) to optimize the triangulation geometry for near-field accuracy. This combination—small size plus high precision—is the hallmark of purpose-built DLP camera solutions designed for these demanding small-space applications.

DLP Technology: The Engine for High-Density 3D Data

Digital Light Processing (DLP) technology is the key enabling factor for achieving high precision within a compact DLP camera unit. A DLP projector uses an array of microscopic mirrors—each mirror corresponding to a single pixel—to project highly accurate, dynamic patterns of light, such as blue fringe stripes, onto the target object. This method offers several crucial advantages over simpler pattern projection techniques:

1. High Resolution and Data Density: The density of the micro-mirrors allows the projection of patterns with exceptionally fine resolution. When the pattern is captured by the camera, this high fidelity translates into a dense, richly detailed 3D point cloud, ensuring that even minute features and surface variations of small parts are accurately mapped.

2. Rapid Capture Time: DLP mirrors can switch states extremely fast (measured in microseconds). This allows the camera to project and capture a complete sequence of structured light patterns—necessary for geometric decoding—in milliseconds. This rapid capture time (as low as 0.2s to 0.7s in some compact units) is essential for maintaining the swift cycle times demanded by high-volume automation processes.

3. Low Profile: The core DLP chip is inherently compact, allowing manufacturers to drastically reduce the overall size of the 3D camera unit, making it perfect for direct mounting on robot flanges where space is a premium. By integrating this rapid, high-resolution DLP projection with refined triangulation algorithms, specialized 3D vision providers can deliver the sub-millimeter precision necessary for complex small-part handling and assembly.

Engineering a Solution for the Collaborative Workspace: The Epic Eye Pixel Mini

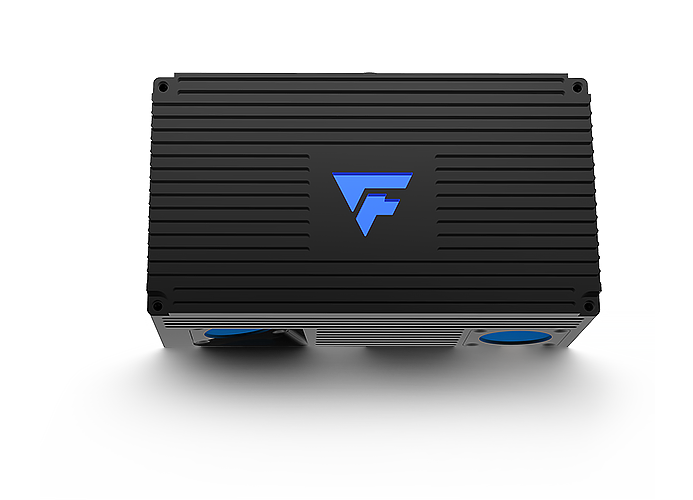

Transfer3D designed the Epic Eye Pixel Mini specifically to address the challenges of high-precision tasks in cramped workspace environments. It is a DLP monocular structured light industrial 3D camera that balances compact size with high optical performance, making it an ideal choice for collaborative robots.

The technical specifications of the Epic Eye Pixel Mini demonstrate how its engineering is tailored for precision close-range work, offering verified metrics critical for B2B integrators:

• Precision: 0.1mm @ 0.5m (A crucial metric confirming sub-millimeter accuracy for small parts).

• Optimal Working Distance: 300-700 mm (Ideal for cobot mounting and close-up inspection).

• Baseline: 85 mm (A very short baseline, optimizing the triangulation angle for near-field data integrity).

• Near FOV (Field of View): 295 x 175 mm @ 0.3m (Confirms the camera’s ability to focus closely and capture the workspace efficiently).

The ultra-compact size (130 x 59 x 73 mm) and lightweight build of the Epic Eye Pixel Miniensure minimal impact on the robot’s payload capacity, allowing maximum efficiency. Furthermore, its typical capture time of just 0.2s~0.7s ensures that the 3D data acquisition process is not the bottleneck in the automation cycle.

Maximizing Small-Workspace ROI with Transfer3D

For B2B customers engaged in automated assembly and quality control, leveraging a camera like the Epic Eye Pixel Mini directly translates into tangible operational benefits. It allows high-precision tasks, previously requiring human intervention or large, dedicated machine vision stations, to be delegated to flexible cobots.

The integration of this specialized DLP camera with Transfer3D‘s 3D Vision Guidance Platform and ATOM Algorithm Platform provides a complete solution. The dense and accurate point cloud data enables robots to perform complex tasks such as bin picking of small, tightly packed metal parts, precise alignment for screw-driving or assembly, and meticulous inspection of electronic components. By providing reliable sub-millimeter accuracy in a compact, fast, and light package, the Epic Eye Pixel Mini enables manufacturers to unlock new possibilities for automated precision in previously inaccessible small-scale workspaces.

Conclusion

In the highly integrated era of automation, overcoming the precision challenges brought by small workspaces is the key to enhancing manufacturing efficiency. Traditional 2D and large-scale 3D vision solutions are no longer applicable.

Transfer3D’s Epic Eye Pixel Mini is precisely a representative born for this challenge. This camera combines fast structured light projection with an ultra-compact size, successfully solving the problems of precision and space limitations in near-field applications.