Across the hydrocarbon and process industries, the paramount priority is the safety of personnel, equipment, and the environment. Central to this safety framework is the immediate and reliable isolation of hazardous process fluids during an emergency. This vital function is performed by robust emergency shutdown systems, where the Neway shutdown valve acts as the final, critical barrier, sealing off sections of a process to prevent catastrophic incidents.

The Mechanism of Rapid Isolation

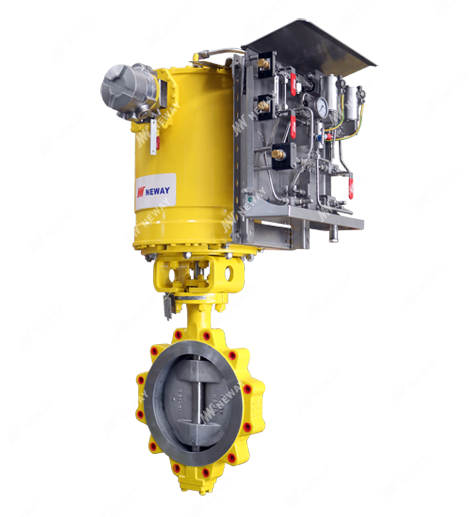

An emergency shutdown valve (ESD valve) is engineered for one primary purpose: to close reliably and instantaneously upon receiving a signal from the plant’s safety instrumented system (SIPS). This signal is typically triggered by sensors detecting abnormal conditions such as overpressure, gas leaks, or fire. Speed and reliability are non-negotiable. For this reason, these valves are predominantly pneumatically actuated, utilizing compressed air or nitrogen for a rapid, fail-safe operation. This makes a pneumatic Neway shutdown valve an ideal choice for inflammable and explosive environments, as it eliminates potential ignition sources associated with electric actuators. The valve’s design—whether ball, gate, or triple-offset butterfly—is selected based on the required sealing integrity and the specific application’s pressure and temperature demands.

Integration and Certification for Maximum Reliability

The effectiveness of a Neway shutdown valve is not solely dependent on the valve itself but on its integration with a suite of control accessories. These can include solenoid valves, quick exhaust valves, and trip valves that facilitate advanced safety functions like High Integrity Pressure Protection Systems (HIPPS) and partial stroke testing (PST). PST allows for regular testing of the valve’s functionality without a full process shutdown, a key feature for maintaining operational uptime while verifying safety readiness. Furthermore, the construction of these valves to international standards such as API 602, API 600, and BS 1873, and their availability in a vast range of sizes and metallurgies, provides the necessary assurance of performance under extreme duress.

Conclusion

In conclusion, the role of an emergency shutdown valve is a cornerstone of modern industrial safety protocols. Selecting a proven and certified Neway Valve shutdown valve provides engineers with the confidence that their safety system has a reliable final element capable of performing its life-preserving function. The integration of robust pneumatic actuation with high-integrity valve designs ensures that when a critical situation arises, the response is instantaneous, automatic, and utterly dependable, thereby safeguarding entire operations from potential disaster.